Acid Zinc-Nickel

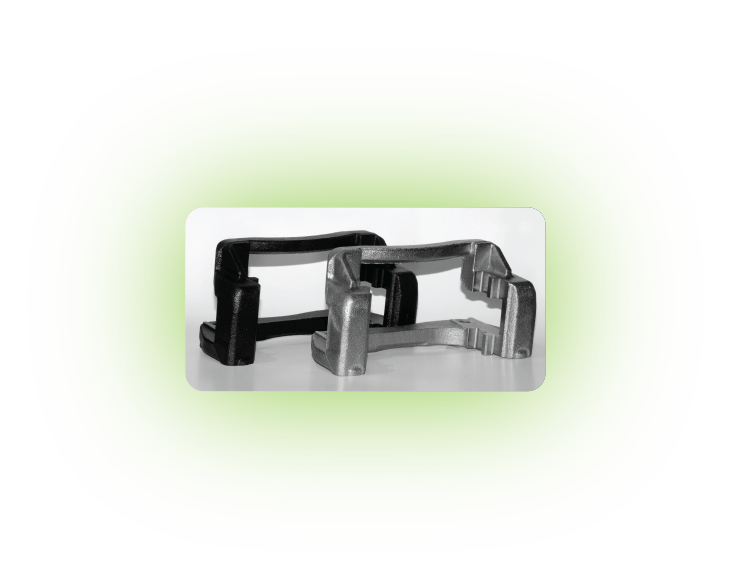

The high efficiency, ammonia and borate free, single rectifier controlled process, provides an easier and lower cost alternative to competitive systems. The system is formulated to provide consistent plating thickness and alloy distribution over a wide range of current densities. The zinc-nickel finish is highly abrasion and thermal resistant, making it ideal for underbody or engine bay environments. With the high efficiency of the process, it promotes excellent coverage over difficult substrates such as castings used for automotive brake calliper applications or high strength steel fasteners. The finish also provides excellent ductility properties and is suited for applications requiring post forming operations.